SANDWICH PANELS

COLD ROOM

|

INDUSTRIAL PANELS

Erkar Industrial Cooling System

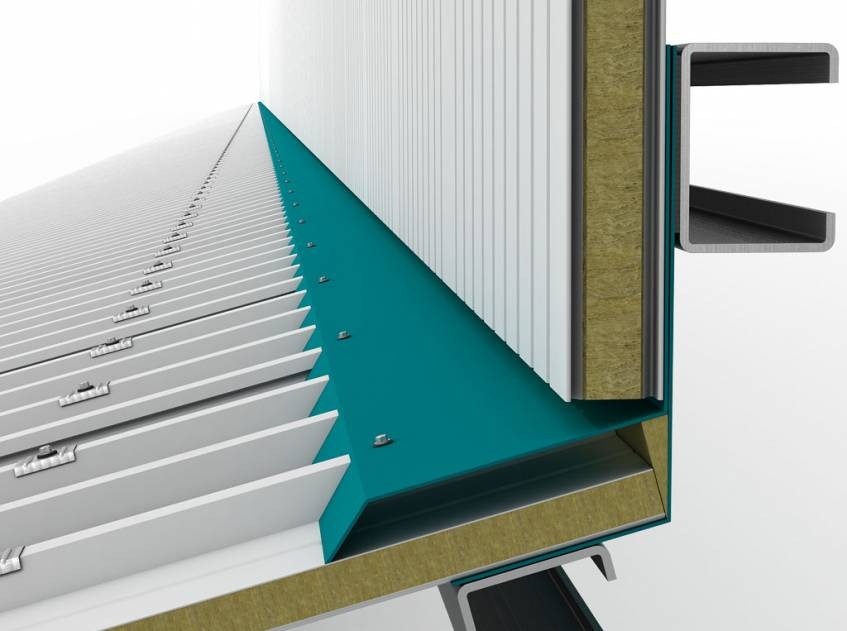

FACADE PANEL

Sandwich Panel is aesthetic materials used as surface coating, composite roof and facade cladding, which is manufactured by applying polyurethane injection of various thickness and density between two layers of painted galvanized sheet or aluminium sheet. Facade panels provide heat, water, sound insulation and fire safety. It protects the building safely from external atmospheric conditions. It is produced as either hidden or external fastening. The produced panels are available in thicknesses of 60, 80, 100, 120, 150, and 200 mm, width of 111 cm and up to 13.5 meters in length according to the project. Its inner and outer surfaces are galvanized sheet metal of 0.50 mm thickness and painted with RALL9002 polyester as standard. Our panels are manufactured according to the lock system and are combined with the detail of interlocking as male and female format. The surface of the panels is smooth, hygienic, and easy to clean. Due to its hygienic nature, it is preferred especially in hospitals, food products warehouses and pharmaceutical industry. It prevents heat loss with its special design and accessories.

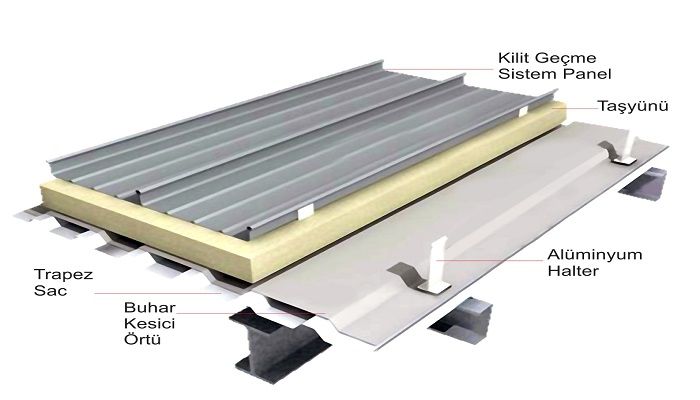

ROOF PANEL

Roof panels are aesthetic materials that protect cold rooms from external factors. Roof panels vary according to carrier systems, roof slopes and covering material. Our roof panels provide maximum heat, sound and water insulation with Rockwool, Polyurethane and Polystyrene Insulation alternatives. The most preferred roofing materials in roof panels are sandwich panels consisting of inner and outer metal sheet and insulation core. Sandwich panels stand out with their high insulation properties in addition to their rapid production and INDUSTRIAL SYSTEM installation, high carrying capacity and lightweight construction

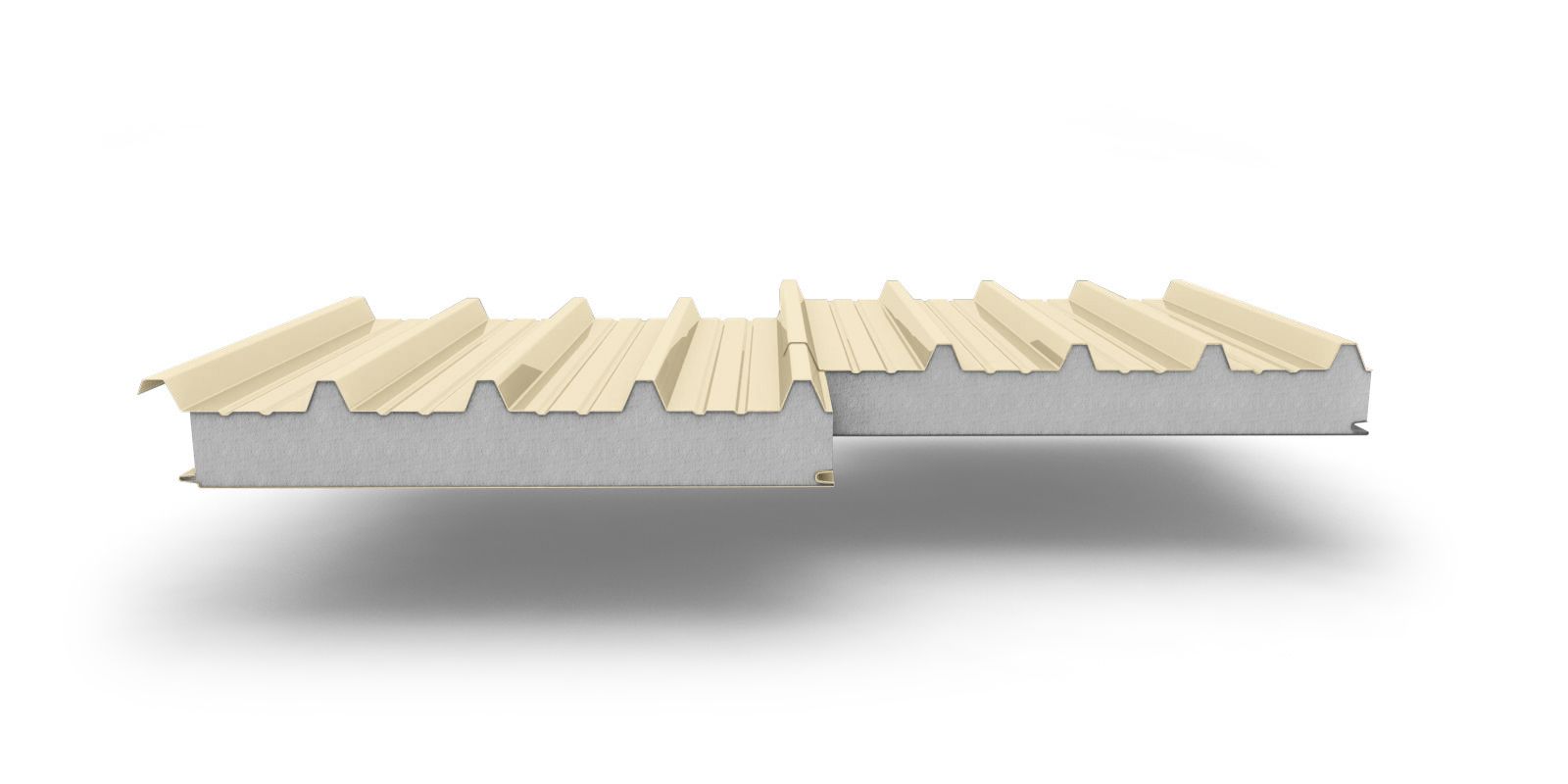

COLD ROOM PANELS

Cold rooms are rooms created to keep foods longer than they can be stored under normal conditions. These cold rooms consist of panels. <strong>Panels are divided into two as a special eccentric lock system or an unlocked screw connection. </strong>With the eccentric lock system, cold rooms are created to provide minimum heat transfer. In this way, foods are stored with less energy consumption under the desired suitable conditions.

Our panels are <strong>CE certified</strong>, filled with polyurethane with a density of <strong>42 kg / m3, </strong>and have a prefabricated structure. We have a wide range of products such as <strong>5-6- 8-10-12-15 -18 and 20 cm</strong> thick chromium, PVC, polyester painted over galvanized, corrugated or non-corrugated in desired sizes <strong>up to 12 meters in length, with locked and unlocked options.</strong> Thanks to the protective film on our panels, it is protected from external factors until the installation process begins. Our products with lock system in female-male form enable the panels to be <strong>assembled / disassembled</strong> without deterioration of their structures.

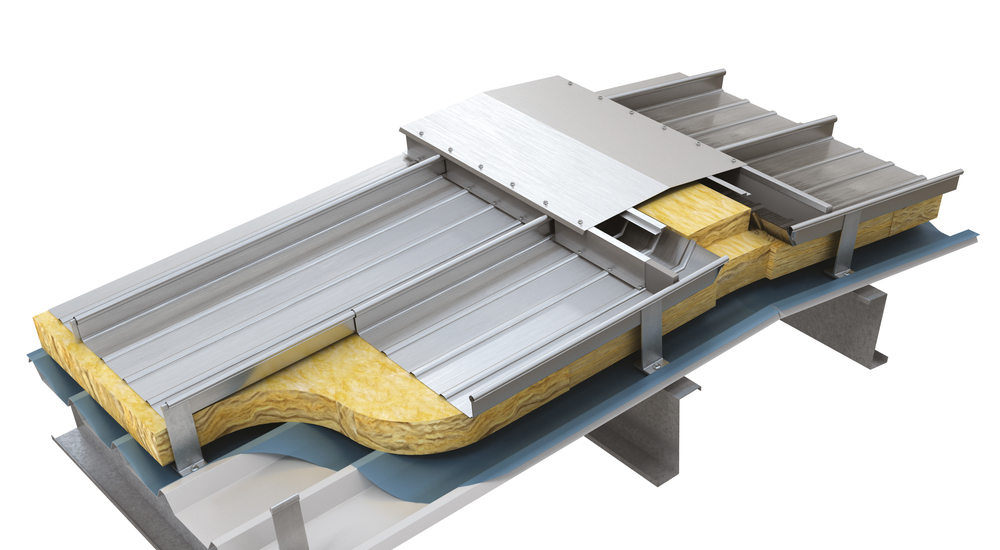

WALL PANELS

Roof panels are aesthetic materials that protect cold rooms from external factors. Roof panels vary according to carrier systems, roof slopes and covering material. Our roof panels provide maximum heat, sound and water insulation with Rockwool, Polyurethane and Polystyrene Insulation alternatives. The most preferred roofing materials in roof panels are sandwich panels consisting of inner and outer metal sheet and insulation core. Sandwich panels stand out with their high insulation properties in addition to their rapid production and INDUSTRIAL SYSTEM installation, high carrying capacity and lightweight construction