BANANA COLD STORAGE

Erkar Industrial Cooling System

The facilities that carry out the necessary procedures to make meat readyfor the customer from the raw state, including animal acceptance, slaughtering, are called integratedmeatplants. Factors such as feeding, breed, type,age, amount of connective tissue, resting before slaughtering, resting of meat after slaughtering, keeping the meat under suitable conditions are the factors that directly affect the quality of the meat. The first task of Integrated Meat Plants is to prevent.

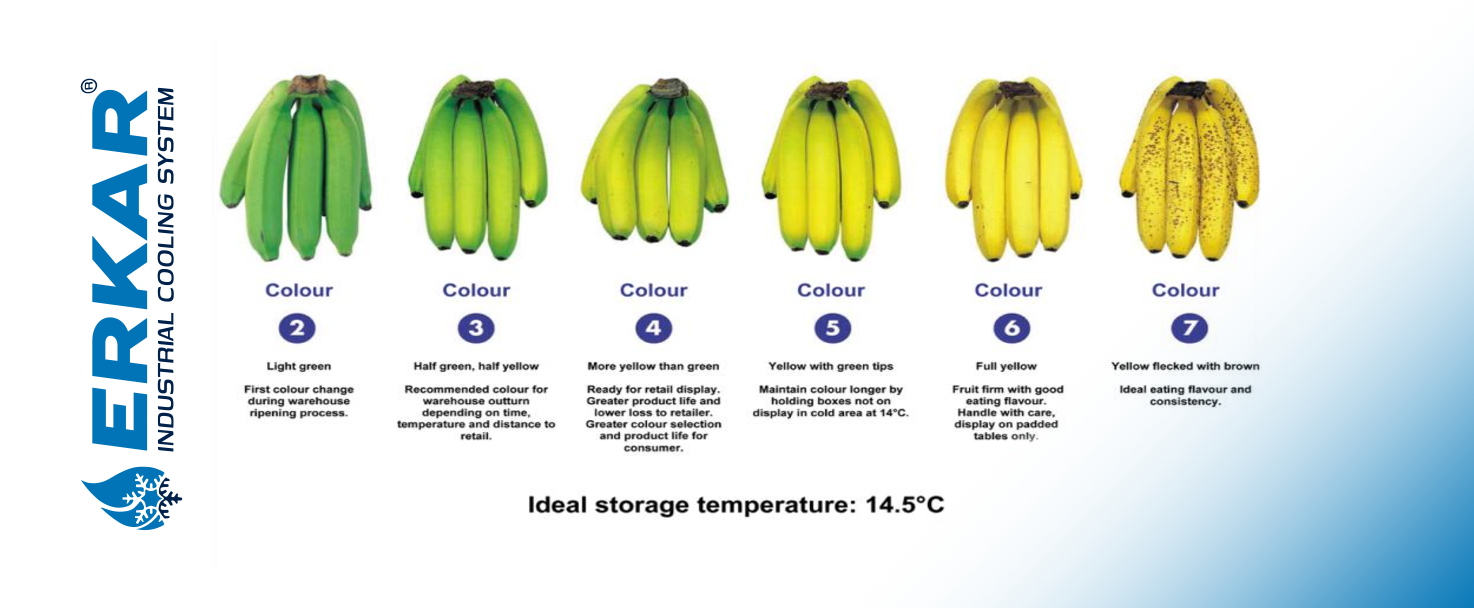

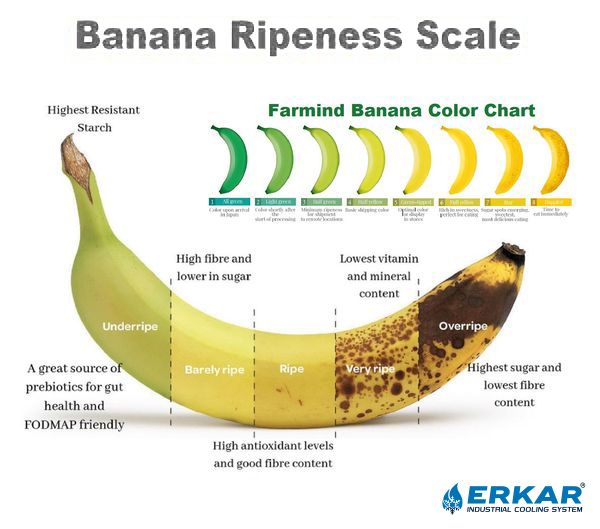

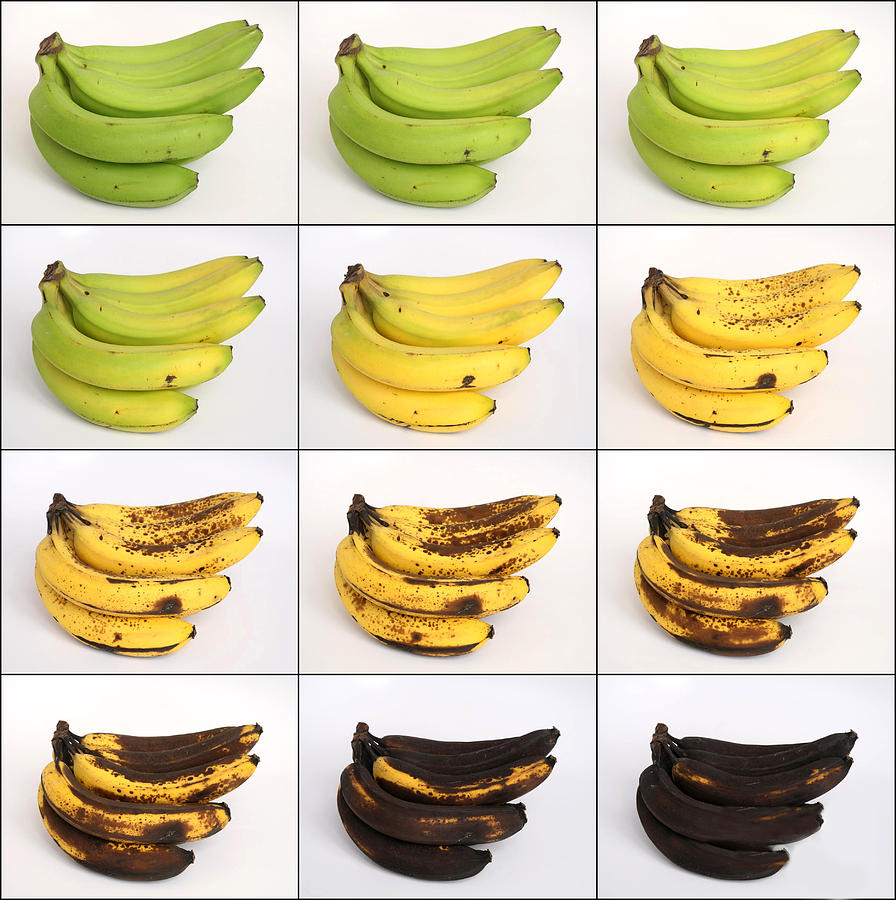

BANANA BROWNING

After the fruits are harvested, the yellowing process is carried out in specially designed rooms with heat and gas insulation, ventilation systems, and temperature and humidity adjustments so that they are ready for the consumer. There are some conditions that must be in the rooms for a successful yellowing process. Such as temperature, humidity, ventilation conditions. The temperature of the room should be 20-28 C and the relative humidity should be 85-95%. The name of the gas used for the yellowing process is ethylene gas. Ethylene is injected into the fruits for yellowing to occur. The room should remain closed for 24 hours after ethylene administration. At the end of this period, the room must be ventilated, otherwise the CO2 level will rise above 1% and this will adversely affect the yellowing process.

BANANA BLACKING

Depending on the types and varieties of the products, the yellowing process is completed in 2 to 4 days. If desired, the duration of the yellowing process can be shortened or extended.

The bleaching rooms should have coolers and cooling systems designed to minimize the moisture loss of the product. Loading systems should be as diverse as single, double and triple storey. The doors of the rooms should be airtight and automatic.