INTEGRATED MEATPLANTS

Erkar Industrial Cooling System

The facilities that carry out the necessary procedures to make meat readyfor the customer from the raw state, including animal acceptance, slaughtering, are called integratedmeatplants. Factors such as feeding, breed, type,age, amount of connective tissue, resting before slaughtering, resting of meat after slaughtering, keeping the meat under suitable conditions are the factors that directly affect the quality of the meat. The first task of Integrated Meat Plants is to prevent.

diseases that pass on to people with meat consumption.Therefore, animals brought to slaughterhouses are kept in paddock for a whilebefore slaughtering. In this process,examination by the veterinarian is carried out. If there is no health problem, they are slaughtered. The area needed for cattle is 5 m2. The area needed for ovine is 0.5 m2.The resting time of the animals varies according to the seasons. It is necessary to rest at least 8 hours in winter, and 12 hours in summer.While these resting positively affect the quality of animal meat, it also helps to diagnose diseases with short incubation period.

Another factor to be aware of is that feeds given to animals should be stopped at least 6 hours before slaughter. Because a large number of microorganisms pass through the intestines of the animals fed before slaughter and decrease the quality of the meat. On the other hand, very few bacteria are found in the blood of animals slaughtered while hungry.

Animals that have been rested in appropriate conditions and have undergone health checks are brought to slaughter rooms.In these halls, tilting, bleeding, skinning and evisceration are performed. Slaughter rooms should be separated into two separate sections as clean and dirty in terms of hygiene.In the clean section, skinning machines are used to prevent contamination of the skin from organisms such as bacteria, etc.

The floor of this section, which should have a ceiling height of at least 6 m, should be made of watertight and non-slippery materials. After the slaughtering is completed and passed the necessary examinations, the carcasses are transferred from the cutting rooms to the resting and dispatching section by the rail system. Carcasses go under rapid cooling process in this section. Then the meat is sent to cold storages, if fresh meat is needed, it is loaded into transport vehicles.

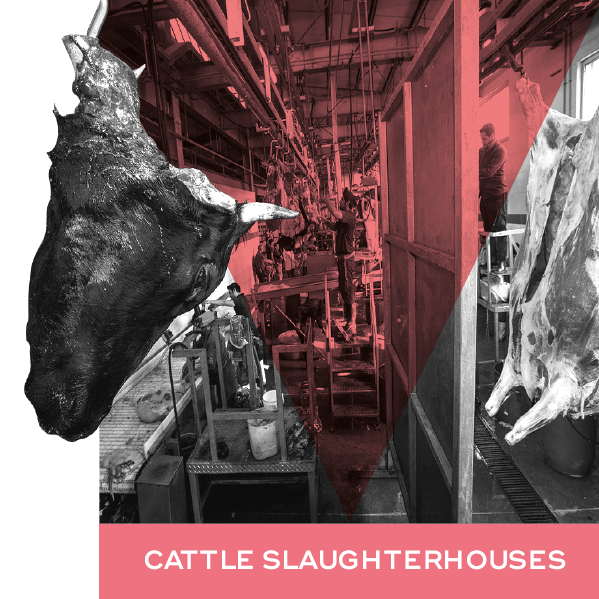

Cattle Slaughterhouse

| Multiphase cutting system is used in these halls. In the multi-phase cutting system, cutting and skinning takes place while the animal is suspended by its hindlimb. There are 5 stages in multiphase cutting system

Phase 1: Cattle are slaughtered, and then bled over. The head is removed from the carcass. It is brought to the 2nd phase with the help of the moving rail system. Phase 2: The skin in the chest and abdomen is removed. Phase 3: The carcass is suspended,and the rest of the hide is skinned. Phase 4: The brisket is cut. Offal is taken out and dropped onto the large moving viscera table. Phase 5: The carcass is split longitudinally by an electric saw into two halves. |

Ovıne Slaughterhouse

The animals are taken under control. Then, animals arepassed over the moving track from their feet. They areslaughtered under suitable conditions.