Our on-duty service personnel meet your demands outside working hours with a gsm number that is open 24 hours a day, 7 days a week. Widespread sales and after-sales service network enables its customers to use suitable and quality products with confidence.

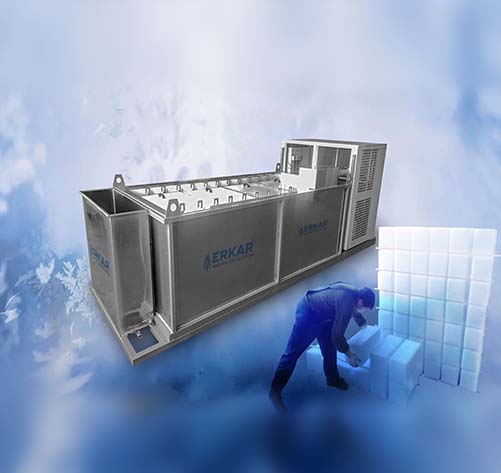

Erkar ICS is a technology and engineering company specializing in “green energy” in the machinery manufacturing sector, producing cooling machines and monitorable cold rooms according to the needs of its customers.